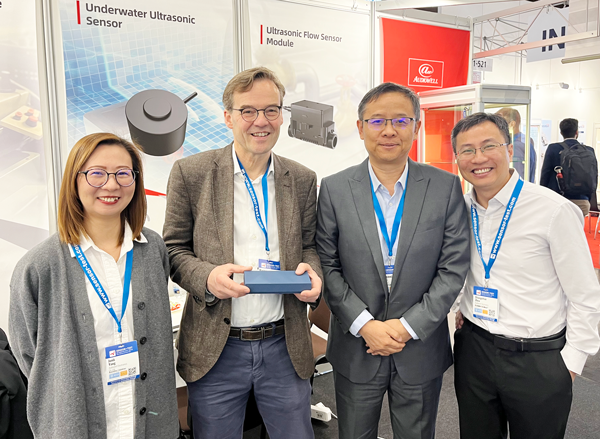

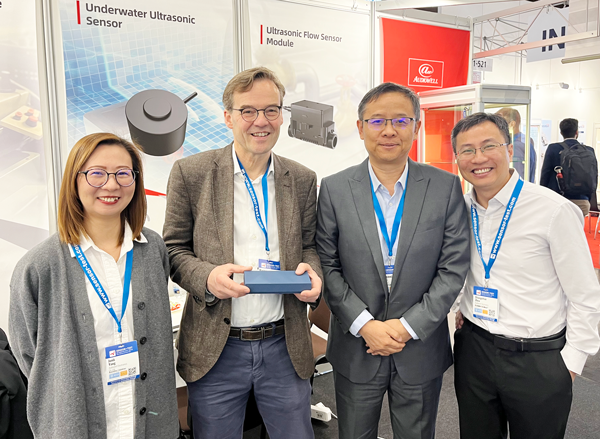

On 11th June, SENSOR+TEST 2024 was officially opened. AUDIOWELL released Lead-free Piezoelectric Ceramic Transducer on the spot, and the first self-developed Piezoelectric Jetting Valve,Piezoelectric Stack appeared on the same stage, which attracted wide attention.

Overseas "debut" of piezoelectric stack

Piezoelectric stack is more than one piezoelectric ceramic film through the thermal compression bonding co-firing process to form a multilayer piezoelectric ceramics, which uses the inverse piezoelectric effect thing electrical energy into mechanical energy, the product has a high-resolution, high-precision displacement, fast response speed, small size, large force and other advantages, in the field of high-precision valve control, micro-displacement console and other fields are widely used.

Piezoelectric technology improves industrial production efficiency and yields

Industrial equipment using piezoelectric stacks as the core control element accurately controls valve switching through tiny differential displacement movements to achieve non-contact, stable and precise output. For example, piezoelectric dispensing valves take advantage of its technology, the piezoelectric stack can quickly respond to the open and closed state, to achieve rapid fluid injection switching, to achieve rapid response and precise control of the injection action, thus improving the production efficiency and product qualification rate.

Micron displacement lifting equipment with high operational accuracy

Piezoelectric stack through the inverse piezoelectric action to generate deformation displacement, its displacement movement can be as small as the micron level, the application of the product's control valves that can be in the micro-cubic volume to control the colloid injection volume output, to enhance the precision of industrial equipment operations.

Vertical stacking structure for high product reliability

The insulating layer on the surface of the product avoids short-circuiting and other problems, and the longitudinal stacked structure design enables the tension to be applied to the entire surface of the product, avoiding wear and tear at a single point of stress, and thus withstanding high pressure and high reliability.

AUDIOWELL's first self-developed Piezoelectric Jetting Valve

Piezoelectric Jetting Valve independently developed by AUDIOWELL is a dispensing equipment used for precise control of fluids (such as adhesives, paints, inks, etc.). The internal core actuator is deformed by the inverse piezoelectric effect when it is energized to push the internal stem, which controls the valve and achieves the precise control of the fluids. The products are widely used in electronic assembly, microelectronic packaging, biomedical engineering, optical device manufacturing and other fields.

Maximum operating frequency up to 3000Hz

The Piezoelectric Jetting Valve has a continuous operating frequency of 1000Hz and a maximum single point operating frequency of 3000Hz, which means that the device is capable of dispensing up to 3000 times per second. Such a high frequency of dispensing action can significantly improve the efficiency of the production line, to ensure the smooth and high-speed operation of the production process.

Minimum spray volume 1nL, high dispensing accuracy

Piezoelectric Jetting Valve with a minimum injection volume of 1nL is able to achieve very small spot size, ensuring that the size and position of each spot is highly consistent; even on uneven or narrow surfaces, it is able to dispense accurately and effectively guarantee the quality of the finished product, which is extremely important for microelectronic packaging, MEMS technology, biomedical engineering and other applications that require strict control of the amount of glue. On the other hand, the use of tiny quantities of material effectively reduces waste and lowers the cost of purchasing expensive materials.

Modular design with small valve body size

The modular design of the Piezoelectric Jetting Valve makes it easier to integrate into automated production lines and work with other automated equipment; at the same time, the components can be quickly disassembled and assembled, making it easy to carry out cleaning and maintenance work. The small size of the product (70mm*42mm*100mm) makes it suitable for all kinds of dispensing equipment with various size requirements.

Suitable for high viscosity colloids, applicable viscosity ≤ 500,000mPa.s

Piezoelectric Jetting Valve with viscosity up to 500,000 mPa.s has the ability to dispense difficult materials (such as adhesives, sealants, pastes, etc.), and is widely used in high-tech industrial fields, such as electronics assembly, automotive manufacturing, medical device manufacturing, etc., which provides more possibilities for the development of new products and innovative production processes for various applicable industries.

Click here to learn more about AUDIOWELL's exhibits.

Focus on us

Focus on us